Austrian Post expands logistics center and parcel sorting building with help from SICK solutions

Logistics is one of the particularly demanding areas of automation, as the number of parcels to be transported is increasing rapidly, with speed and reliability being decisive factors. To cater to this growth, Austrian Post commenced an expansion of its logistics center in Allhaming (Upper Austria) in April 2021. In addition to expanding its parcel sorting facility, the company built a new distribution center and office building.

Upgrade to highest performing location

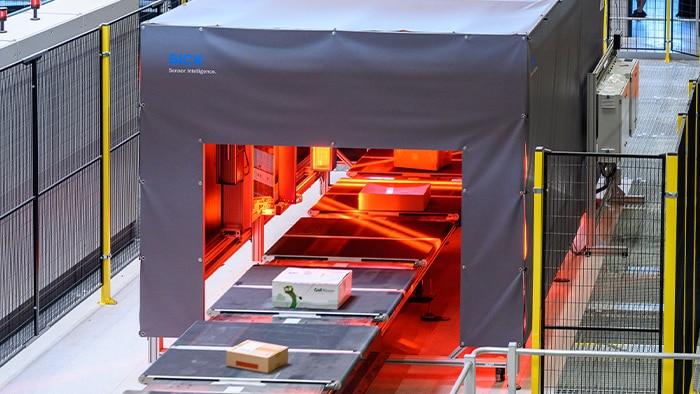

The existing systems at the logistics center dated back to 2014, so they needed an upgrade. The new high-performance sorting machines commenced test operation in August 2022, where their integration with the modernized systems was extensively tested. Nothing can be left for chance at speeds of up to 30,500 parcels per hour. Following this expansion, the parcel logistics center in Allhaming is now the highest performing location in the Austrian Post network. The official opening took place in October 2022.

Ten thousand parcels per hour are scanned and sent on their way by Austrian Post in its logistics center in Allhaming.

Tripling the parcel sorting capacity

Around 900 employees now work at the Allhaming location. The total investment cost of the expansion project was about 80 million euros. The new building complex occupies approximately one quarter of the 200,000 sq. m. property. This expansion has not only tripled the parcel sorting capacity, but is also setting new benchmarks in terms of sustainability. The site was upgraded with green areas with bushes, trees and flowers for wild bees, nesting boxes for birds, and a biotope. Installed on the greened biodiversity roof of the new building is a photovoltaic system with a capacity of around 500-kilowatt peak (kWp). When fully completed, this is expected to deliver around 1.5-megawatt peak (MWp) and produce green electricity for the site’s operations and e-vehicles.

“The logistics center is a flagship green-yellow project,” said Dr. Georg Pölzl, Graduate Engineer and CEO of Austrian Post, at the opening of the facility.

Besides developing a comprehensive traffic concept to eliminate any impact on local traffic, the issue of efficiency, including inside the building complex, was given particular importance.

Test operation in August 2022: The integration of the newly installed machines in the modernized systems was extensively tested.

1.7 million letters and 330,000 parcels per day

The expanded Upper Austria logistics center now serves as the logistics heart of Austrian Post and, thanks to its sorting capacity, is also one of the top-ranking facilities in Europe. To achieve this, the existing sorting machines were upgraded to state-of-the-art high-efficiency track and trace systems from SICK. The Allhaming facility can now process up to 330,000 parcels and 1.7 million letters for domestic and international delivery per hour at peak times.

Reliable identification at high speeds

The ICR 890 (Image-based Code Reader) track and trace systems can identify all commonly used 1D/2D codes and postal codes at fast conveying speeds up to 4.5 m/s. The outstanding image quality of the integrated camera (min. 200 dpi) makes it possible to use OCR, video coding, and vision applications. To the delight of the eagerly awaiting recipients, they can use the Post app, which can automatically capture, store and process images of multiple sides of the parcels. And in the event of complaints, it’s possible to determine from the images whether visible damage was already present when the parcel arrived at the logistics center, which is especially important for large customers who also deliver their parcels to the logistics center themselves.

Easy modernization and expansion

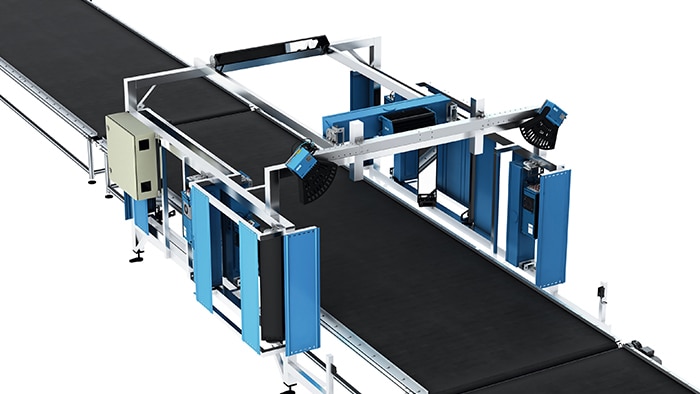

The 1,200 mm carrier width of the 1200 HC CROSSORTER from Vanderlande is significantly less than the up to 1,600 mm width supported by the current ICR systems from SICK, which have only one camera on board. A further advantage is the modular design of the system, which made it feasible for the postal service to upgrade its existing equipment and made it possible to integrate additional sensors, like a volume measurement system.

“We wanted a fully integrated solution. It was therefore absolutely essential to upgrade the existing equipment. In doing so, we sought to incorporate the additional desired functionality – for example, capturing parcel details on all sides – while also taking into consideration the limited space in the existing building. The modular design of the systems and our longstanding collaboration with the experts at SICK were of great benefit to us. With a project of this size, there will always be changes, so it is important to be able to quickly access a competent contact who can help you find a solution. Manfred Dietachmair and the team in SICK’s network of experts excelled in this regard,” said Oliver Deick, Technical Manager Logistics Infrastructure at Austrian Post.

Manfred Dietachmair (left), Sales SICK Austria and Oliver Mosböck (right), Technical Manager Logistics Infrastructure, Austrian Post

Volume as an additional measure

“Our goal was to significantly increase the read rate while at the same time capture additional information. In addition to the weight, the volume and dimensions are also becoming increasingly important. In particular, when it comes to optimizing the transport of the parcels, the volume is a relevant factor for the transport capacity, not just the weight. These measures are also required for billing purposes. That is why, for example, we automatically capture them and forward them to the billing systems when we receive parcels directly from large customers. These measures must always be correct. It was therefore a big advantage for us to be able to integrate these measurement systems into our controllers, even with the existing data tunnels – which is how we refer to our data capturing systems,” explained Oliver Mosböck.

Dimensioning, Weighing, and Scanning

In selected areas of the logistics center, Austrian Post is now employing an innovative end-to-end solution that can capture all currently relevant data at once. These DWS (Dimensioning Weighing Scanning) systems from SICK measure the parcels, weigh them, and scan the labels applied to multiple sides. The ICR890 code reader is also used for this. A laser-based volume measurement system (VMS) delivers the dimensions of the packages, and a scale records the weight while the parcels are moving. Flexibility is another key feature. Thanks to the modular system design of the DWS, future upgrades or conversions are no issue. “Everything here fits together excellently. The hardware package is supplemented by the perfectly tailored analytics software package that monitors the individual components and clearly displays their performance in dashboards,” explained the Technical Manager Logistics Infrastructure at Austrian Post.

DWS systems measure the parcels, weigh them, and scan the labels applied to multiple sides.

One data record for everything

Every sensor delivers data. This means each parcel has a multitude of information coming from a wide variety of sensors associated with it. Administering, merging, and “marrying” this data with the shipment data is often an IT challenge of the highest order. “SICK accomplishes this using standardized interfaces and a data record that already contains all the necessary information. The postal service’s host system therefore receives a complete, already pre-processed data string from the data tunnel, including a tracking ID. The data merging occurs directly on-site in the machines – an important aspect that makes further data processing significantly easier,” said Dietachmair, the responsible sales specialist at SICK Austria.

The data tunnels provide the host system at Austrian Post with a complete data record – including a tracking ID.

Ready for the challenges of tomorrow

With its ultramodern logistics center in Allhaming, Austrian Post has upgraded an important hub in its network to the state of the art so that it can also cope with future challenges: “The expansion of this location has created additional flexibility. The market environment here is very volatile. The new solutions are an important component of ensuring that our customers can receive their parcels quickly, even at peak times,” said Mosböck.

Want more information about improving your logistics processes?