Autonomous Cleaning Robots are Sweeping the Globe

The market for autonomous cleaning robots is growing rapidly. Experts estimate that by 2025, there will be five times as many robots in use as there are today. No wonder, given the market for skilled workers has dried up along with enormous economic pressure in the industry.

As the use of automated cleaning machines increases in more and more areas of public life, like in airports, manufacturing halls, hospitals, or supermarkets, safety requirements have become even more stringent. Consequently, the IEC revised the standards in June 2021 and issued new standard requirements.

Kärcher, a leader in cleaning machine manufacturing, developed its autonomous KIRA B 50 scrubber dryer robot in accordance with these standards in collaboration with SICK, thereby placing itself at the top of the market for cleaning robots.

A (quite literal) safety net: comprehensive support from SICK

Developing an automated cleaning machine harbored quite the laundry list of challenges, ironically. Luckily, Kärcher could turn to SICK for assistance with the personal safety concept, as they’re in a long term partnership in the area of hardware. Kärcher was able to rely on SICK’s strong network of experts for all issues relating to safety in robotics.

“Besides providing 360 degrees of protection and implementing a fall protection feature, it was especially important that the sensors have a compact design. The cleaning robot needed to be able to efficiently master not only corridors and tight spaces, but also cornering, and be able to safely detect obstacles and navigate around them. Satisfying the requirements of all the new standards was, of course, a top priority,” Andreas Rendler, Strategic Product Manager at SICK.

The nanoScan3 provides 360 degrees of protection.

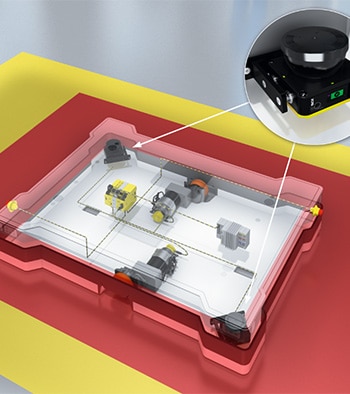

The name behind Kärcher’s autonomous cleaning robot

To ensure the KIRA B 50 could truly live up to its name (an acronym of “Kärcher Intelligent Robotic Application”), Kärcher and SICK put their combined expertise into the planning, design and trialing of the cleaning robot. SICK provided their advisory support with the implementation of the demanding safety concept. The result: an intelligent robot application guided by three nanoScan3 safety laser scanners and the Flexi Soft safety controller. They ensure that the environment perception of the cleaning robot is not only focused on optimal navigation, but also ensures the safety of persons in its environment.

Alina Seitter, Product Manager KIRA B 50 at Alfred Kärcher SE & Co. KG. and Andreas Rendler, Strategic Product Manager at SICK, trust the tailored sensor concept based on the nanoScan3 safety laser scanner.

Fall protection and more with nanoScan3

“One of the first key challenges was the all-around protection for the KIRA B 50, because the cleaning robot moves both forwards and backwards. We found the optimal solution for this by locating two nanoScan3 devices at diagonally opposite corners of the vehicle,” said Alina Seitter, Product Manager KIRA B 50 at Alfred Kärcher SE & Co. KG.

Thanks to the wide scanning angle of 275 degrees and their large protective field range, these lasers provide horizontal all-around protection, thereby meeting the new IEC 63327 safety standard.

To meet the key requirement for fall protection, a third nanoScan3 safety laser scanner was added, as many public environments such as supermarkets, university buildings, or airports pose a safety risk to autonomous robots on account of their escalators, stairwells, and ramps. Kärcher therefore equipped the KIRA B 50 with a nanoScan3 as a “cliff LiDAR” for fall protection.

Mounted on the front side of the autonomous cleaning robot, it detects the floor in front of it at an oblique angle. As soon as the nanoScan3 detects an abrupt height difference, a signal is sent to the Flexi Soft safety controller. Further movement in the direction of the potential fall edge—a step, for example—is stopped, and the navigation unit selects an alternate route.

The compact design and small size of the nanoScan3 also makes it easier to optimally locate the sensors. Being one of the smallest safety laser scanners on the market, it integrates into the machine design of the KIRA B 50 in a space-saving manner.

Versatile use – KIRA B 50 the safe cleaning robot is used in public spaces.

Friends in tight places: Productivity and efficiency

The requirement for safety in narrow corridors, tight spaces, and when cornering is met by the special safety functions of SICK's safety system, which allow the protective fields to be selected based on the speed and steering angle. The following applies: The greater the speed, the larger the scan fields need to be to enable the vehicle to come to a safe stop before an obstacle. At the same time, the safety fields should be as small as possible to avoid unnecessary speed reductions and stops.

The safety system from SICK resolves this problem with the steering angle dependent switching of up to 128 protective fields, a feature of the nanoScan3. On one hand, this increases the productivity of the cleaning robot in narrow gaps and rooms. On the other hand, the dynamic protective field switching in large open spaces allows higher speeds and subsequently, greater efficiency.

On a cleaning mission! Thanks to the 128 protective fields generated by the nanoScan3 sensor, KIRA moves easily in narrow spaces and rooms.

Seitter underscores the importance of the safety functionality.

“Safety is the number one priority for Kärcher and we can one hundred percent rely on this safety concept for the autonomous operation of our cleaning machines when there is no one on site to intervene,” Seitter said.

SICK assisted Kärcher with obtaining the necessary Performance Level d certification. Seitter is impressed with the overall result of this collaborative development: “KIRA was created in close collaboration with SICK. Reliable and intelligent sensors are enormously important in robotics, and we found SICK to be an especially experienced supplier.”

Straight to the spick-and-span outcome

As one of only a few suppliers that can offer complete safety systems, SICK equipped the KIRA B 50 with the sensors it needed to ensure the cleaning robot operates reliably and safely. From the safety laser scanners and safety controller to the safety encoder, Kärcher obtained everything from a single source, including expert and trusting support with the certification.

The tailored safety concept of the KIRA B 50 is the result of an ongoing and close dialog with Kärcher.

“We were very pleased that Kärcher requested our support very early in the development process. This enabled us to use our expertise and know-how to help the customer achieve their desired safety concept quickly and directly,” Rendler said.

Just the beginning: Kärcher has plans for a whole fleet of autonomous cleaning robots.

With its innovations in safety-certified autonomous cleaning robots, Kärcher intends to provide the industry with solutions for becoming more productive, profitable, and to effectively counter the problem of staff shortages. The market leader regards the KIRA B 50 as just the beginning.

“We are planning to create a whole fleet of autonomous cleaning robots, and because the sensors and safety controller from SICK are a fundamental part of our sensor concept for KIRA, they will no doubt be used in more model series in the future,” Seitter said.

Want to learn more about autonomous cleaning robots?