Radio frequency identification (RFID) provides significant benefits for the preventive maintenance and monitoring of railways all over the world

Hundreds of derailments occur on railroads every year. According to the D-RAIL project, an average derailment has an impact of nearly a million dollars. Some of the reasons these accidents occur include wheel, axle, and suspension failures due to wear and tear, as well as incorrect loading. To fix this several hundred million dollar problem, vehicle owners are investing in preventive maintenance and monitoring systems. This requires a complex infrastructure of wayside train monitoring systems (WTMS), such as hot axle box detectors (HABD), axle load checkpoints (ALC), and other devices (ultrasonic sensors, high-resolution cameras, etc.) along the rail tracks.

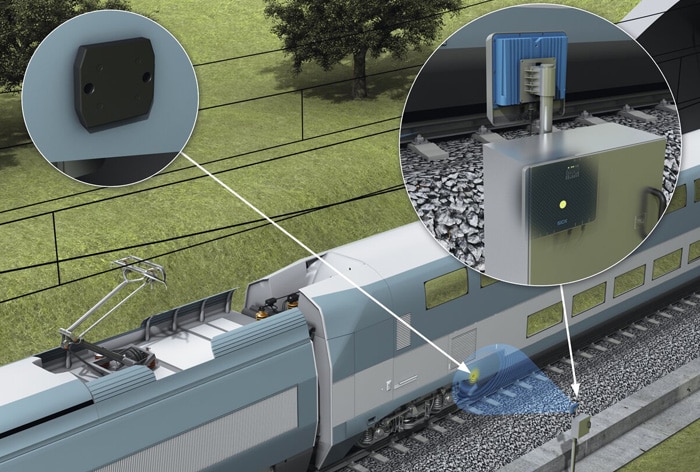

These systems have already been in place for years. Why add RFID into that process by tagging each train wagon with on-metal UHF RFID tags and mounting RFID long-range readers at the WTMS? Well, the additional information of the unique RFID tag will enable a link between the critical measured values (detected failure) and the specific vehicle, wheel set, axle, brake, and suspension. Using RFID allows you to know in advance which part requires rework. RFID also provides the following benefits:

- Reducing maintenance costs

- Reducing high-cost emergency maintenance

- Better planning due to real-time information about the vehicle’s condition

- Higher availability of rail vehicles and better reliability during operation

Asset tracking – know where your train is

In addition to improving preventive maintenance, implementing RFID on railroads allows for real-time asset tracking. This gives all involved parties the answers to what, where, when, and why. For example, companies in cargo transport can finally have an answer when their customer asks, “Where are my goods/ cargo?” There are also the additional benefits of better planning for vehicle availability and a reduction in unused capacities.

Why use RFU630 from SICK?

During work on a project with Trafikverket, the Swedish transport administration, the team at SICK identified features that contributed to the success of the project.

- Industrial design

- Ruggedized housing EN 50125 (shock vibration)

- Solid electronics compliant with rail norm EN 50121 (EMC)

- Wide operating temperature range -40°C to +60°C (RFA630)

- Outdoor IP67 protection class

- Fast data processing

- Read tags > 200km/h

- Accurate time stamps

The SICK RFU630 was the solution for this project. This is a UHF RFID read/write device combined with sensors that count the axles. This is a necessary asset when assigning the tag to the vehicle/wheel-set, providing speed, direction of travel, orientation of vehicle, and ordering vehicles within the train.