SICK’s GM32 in-situ gas analyzer helps reduce emissions and protect the environment

Environmental awareness is growing in all major manufacturing industries worldwide— even the cement industry. The emission of hazardous substances and environmental pollution should be reduced or prevented in any possible way. Modern cement producers are following suit with two important goals: effectively supporting climate protection and maintaining and restoring a clean environment. The motivations are manifold, be it due to new environmental legislation, pressure from the local population, external organizations and interest groups of the company, or self-imposed sustainability obligations. Gas analyzers can help make this an easier process.

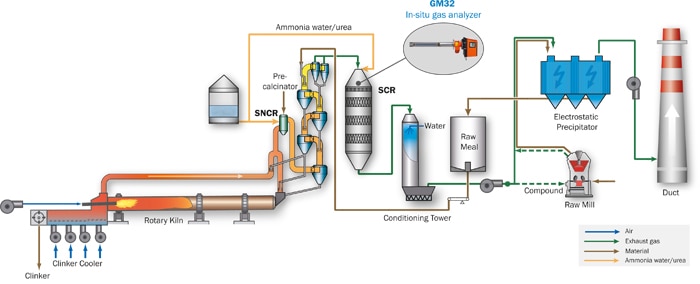

Figure 1: GM32 on site during preventive check-up

NOx emissions and regulations

Nitrogen oxides (NOx) and other nitrogen compounds arising from cement production are considered the main reason for photochemical smog and formation of nitric acid and acid rain. They are formed either by a combination of fuel-based nitrogen with oxygen within the flame or by a combination of atmospheric nitrogen in the combustion air. The two main mechanisms for the production of NOx in a clinker burning process are the reaction of nitrogen in combustion air at high temperatures (thermal NOx) and the combustion of nitrogen containing fuels (fuel NOx). Globally, the emission limits for NOx show the same trend toward lower emission standards and stricter penalties for non-complying plants. However, there are still big differences for this pollutant. Most national limits are in the region of 500 to 1,000 mg/Nm3. Some plants in the EU take pioneering roles by having fixed emission limit values down to 200 mg/Nm³, depending on which kiln process is applied and what type of fuels are being used.

Even though primary measures such as flame cooling, installation of low-NOx burners, staged combustion and general process optimizations show significant effects in reducing NOx emissions, secondary measures are also vital for NOx abatement as they lower emission limit values. In cement production, two secondary measures, selective catalytic reduction (SCR) and selective non-catalytic reduction systems (SNCR), have consistently gained popularity over the last few years. They are accepted and proven technologies when controlled in a proper way.

SCR and SNCR – two technologies, one goal

SCR and SNCR denitrification (DeNOx) plants use ammonia (NH3) for an efficient reduction of NOx to form the harmless nitrogen and water. The main difference between both technologies is the use of a catalyst. The SNCR, i.e. DeNOx, without a catalyst, is installed in the riser duct or calciner after the rotary kiln at a temperature range of 900 to 1,000 °C. Depending on the type of SCR, it can be placed in the high dust raw gas stream (e.g. directly after the pre-heater) or before the main stack in the low dust gas stream as a so-called tail-end or low-dust SCR. A SCR consists of a specific number of catalyst layers and operates at a gas temperature of around 300 to 350 °C. The reducing agent, typically ammonia water or urea, is injected at the SCR inlet.

For an initial reduction of NOx emission values, often a SNCR is sufficient and lower in cost to install than a SCR. An efficient reaction between the NH3 and NOx depends highly on the temperature. At temperatures greater than 1,200 °C, NH3 converts to NOx; at temperatures lower than 800 °C, the ammonia slip increases. Thus, an efficient and well-adjusted control of the ammonia injection is of high importance for the compliance of gas emission limits when using a SNCR. The presence of the catalyst in the SCR allows operation at lower temperatures and offers a higher stoichiometric ratio, which leads to a lower amount of injected reducing agent and ensures a lower NH3 slip. Thus, very low NH3 and NOx emission limit values can be adhered to.

Figure 2: Cement diagram illustrates the production and gas flow and identifies the measuring point

The gas analyzer project: HeidelbergCement Geseke

With the growing demand for SCR and SNCR units in cement production, the need for a measurement technology that can be used to efficiently control these plants is also increasing. According to new emission limits from January 2019, (enacted in 17. BImSchV; Federal emission control act), 200 mg/Nm3 for NOx and 30 mg/Nm3 for NH3 is required. To comply with local emission regulations, HeidelbergCement decided to invest in a SCR plant in addition to the already existing SNCR solution. HeidelbergCement Geseke finished the commissioning of the new high dust SCR plant in March 2019.

Project planning and implementation addressed the question: Which kind of analyzer could fulfill the requirements for an efficient SCR control? The device should be placed at the SCR inlet between the ammonia water injection nozzles and the catalyst (see figure 3).

Of high importance were the analyzer’s fast response time for efficient control of the ammonia water injection as well as a long maintenance-free period under these very challenging conditions. The advantage of the measuring location at the inlet is the simultaneous measurement of NH3 and NO entering the SCR. Here, NH3 is the sum of ammonia evaporation from the raw materials, the ammonia slip of the SNCR and the ammonia water injection for the SCR. The NO originating from the combustion process could also be measured. With this measurement and the Continuous Emission Monitoring System (CEMS) at the main stack as backup, a feed forward control would be possible.

In the project planning phase, HeidelbergCement contacted SICK to provide a solution that best fit the requirements mentioned above. As the only provider for all major gas measuring principles and technologies coupled with many years of experience, SICK was able to select and provide the best measuring technology for each application. In this case, SICK decided to provide a GM32 in-situ analyzer to manage the very challenging process conditions — high dust, high temperature and vibrations.

Figure 3: Installation point of GM32 onsite at the SCR inlet at HeidelbergCement Geseke plant

GM32 – the innovative in-situ gas analyzer

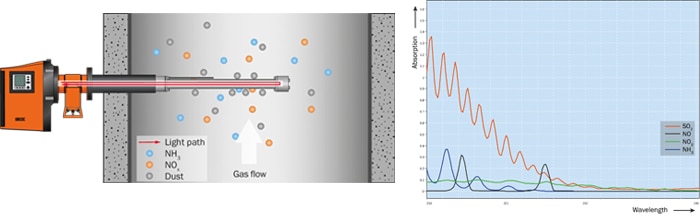

The in-situ gas analyzer GM32 from SICK simultaneously measures up to four components (NO, NO2, NH3, SO2), plus temperature and pressure, directly inside the process gas stream. The direct measurement inside the duct (in-situ) leads to fast measuring results due to a short response time, which is perfectly suitable for process control. The GM32 analyzer unit is equipped with a gas permeable probe (GPP), which is positioned inside the duct (see figure 4). Using the wavelength-specific light absorption by the gas mixture on the active measuring path, the sender/receiver unit determines the concentration of the gas components present. UV light sent from the sender/receiver unit passes the active measuring path of the GPP probe and is reflected by a triple reflector at the end of the probe. The permeable filter element — the heart of the GPP— keeps all dust outside of the measuring path, where the light passes through, while the gas quickly permeates through the pores, ensuring the required fast response time. The GM32 uses the DOAS principle (Differential Optical Absorption Spectroscopy) where the absorption lines of specific gases in a particular wavelength range are evaluated.

Neither the filter nor the rest of the gas analyzer require weekly or monthly checking, cleaning or other frequent maintenance work.

Due to the higher temperature and possible temperature fluctuations at the measuring location, stack movements are possible. With the implemented auto alignment correction, which continuously aligns the light beam during operation, stack movements and vibrations can be compensated for. This ensures a stable and reliable measurement.

In comparison to many other measuring systems, which require a frequent test gas calibration, the integrated filters for zero and span check (approved according to EN15267) automatically compensate drifts and ensure a correct and accurate measurement. This also helps to keep operational expenditures very low.

Figure 4: GM32 measurement technology: optical path and UV absorption spectra

Test run: GM32 v. CEMS

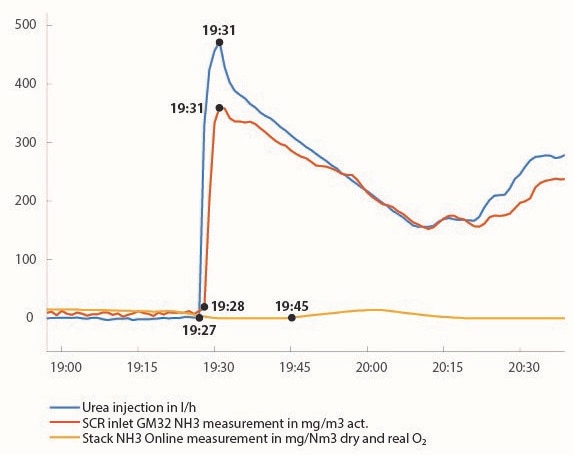

The final commissioning of the in-situ gas analyzer at HeidelbergCement plant Geseke took place in March 2019 (figure 3). During the 12-month testing period (March 2019 – March 2020), SICK and the cement plant proved that the GM32 has to be checked regularly in this application, but only every 9 to 12 months. With the help of remote service (SICK Meeting Point Router), on-site tests were performed and a large amount of additional process data, like the CEMS concentration values at the main stack, was collected and evaluated in various aspects. The test period proved that the analyzer has a stable reaction time of <20 s (figure 5), without the need of any cleaning and smaller or larger maintenance works. The results show that with a delay of 2 to 17 minutes (depending on the measuring component), a CEMS alone is not sufficient for DeNOx process control.

The NH3-value for CEMS, especially, has a huge delay in comparison to the in-situ gas analyzer process gas measurement (figure 5) due to the high adsorption of ammonia on surfaces (e.g., filter and heated measurement lines). Controlling the SCR with such delayed measuring values will lead to an excessive injection of ammonia water and a faster exceedance of the NO and NH3 emission limit values at the main stack. Therefore, SICK’s GM32 in-situ measurement device has proven to be the right device for this kind of application.

Figure 5: Comparison of NH3 response times between GM32 in-situ measurement at SCR inlet and CEMS at main stack

“We are very satisfied with the performance of the GM32 gas analyzer. The GM32 project was executed fully compliant to the requirements and schedule. We are looking forward to continued good cooperation,” said Dr.-Ing. Steffen Gajewski, Plant Manager & Dipl.-Ing. Stefan Naber, Operations Manager, HeidelbergCement Geseke.

Remote Service and Condition Monitoring

For the future, SICK and HeidelbergCement are planning to implement SICK’s Monitoring Box to offer predictive maintenance services for all gas analyzers and dust measurement equipment installed on-site. The solution allows SICK to optimize maintenance, to monitor critical components or device conditions and to make remote product health inspections that recommend maintenance actions. This will enable immediate troubleshooting, which again, reduces travel expenses and labor hours for service engineers. Furthermore, continuous remote condition monitoring combined with remote assistance and agreed response times assure compliance with local emission regulations, process stability and continuous production.

Inspired by the successful partnership between SICK and HeidelbergCement’s plant in Geseke, another HeidelbergCement plant in Germany decided to equip its DeNOx system with two GM32 analyzers for SCR control, too. The commissioning of these devices took place in June 2020. This, together with an open and intense information exchange during various environmental and process seminars, have contributed to a strong partnership between SICK and HeidelbergCement.

Check out another project with SICK and HeidelbergCement: