The operator of a Spanish port terminal joins the list of customers now using Smart Data Solutions from SICK

On course for destination Industry 4.0 – MSC Terminal Valencia is taking advantage of Condition Monitoring from SICK in order to increase the availability and reliability of its quay cranes and reduce downtimes. It also enables them to optimize the timing of maintenance work on the sensors.

Eight driverless quay container cranes move back and forth over a 770-meter stretch. With great precision, each individual crane transports over 40 containers per hour from the ships to the terminals and vice versa. Sensors from SICK are contributing significantly to this automation in the wharf area. The 2D LiDAR sensors, LMS1xx and LMS5xx, enable processes to be automated even in harsh environments.

The conditions in the Mediterranean on the southeastern coast of Spain can be harsh year round. Contamination from layers of sand or salt deposits impair the field of view of the sensor. Heat and cold can also impair the sensor technology. Regular inspections and maintenance are therefore an essential preventive measure.

A Benchmark for Global Trade

With an annual turnover of over 1.5 million Twenty-Foot Equivalent Units (TEUs), the MSC Terminal Valencia is an important logistics hub for the Mediterranean Shipping Company, one of the largest container shipping lines in the world. As the rate of globalization increases, the international movement of goods is accelerating as well.

Port terminals in particular are feeling the pinch, which is why they need to continuously improve their efficiency, digital networking and plant availability. When it comes to efficiency considerations, industry 4.0 implementation looms large. The pioneering Smart Data Solutions from SICK can also be retrofitted to existing ports.

Web-based Condition Monitoring

“The key to a sustainable foray into Industry 4.0 applications lies with the sensors,” said Max Dietrich, Product and Application Manager for Smart Data Solutions at SICK. “Our sensors can deliver data that become all the more valuable the more we process them into relevant information and make them transparent.”

Until now, port terminal operators have been relying on their internal maintenance team to check and clean the crane sensors at regular intervals.

“That costs us about a half a day of work per crane every 8 weeks,” said Javier Campos, Maintenance Engineer at MSC. The big unknown is whether the servicing on the difficult to access cranes might have been performed too soon. Was all that effort and expense really warranted at that time?

Condition Monitoring helps ensure the correct functioning of the sensors. Using the data from the sensors, it is possible to monitor the sensor values and optimize numerous settings and processes. These digital services help avoid unplanned downtimes of the cranes or in the yard area. These Smart Data Solutions were promising to maintenance engineers at MSC Terminal Valencia.

“The Monitoring Box on the quay crane makes the environmental influences on the sensors visible. We can monitor this information on the dashboard either retrospectively or live, and use it to develop a significantly more efficient maintenance schedule,” Campos said.

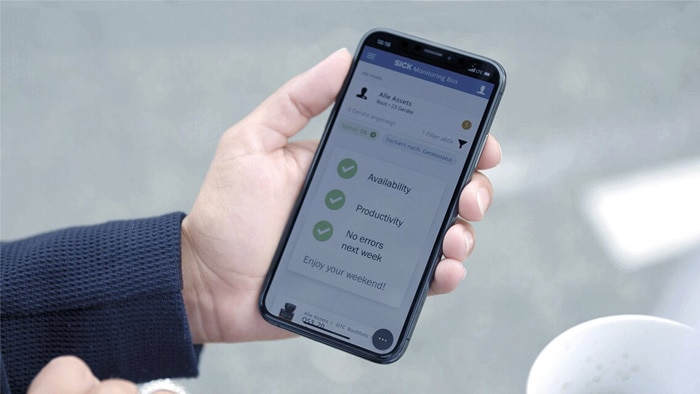

It is also possible to receive an email notification when a defined threshold is exceeded for a sensor. The current status of the sensors can also be viewed on the dashboard at all times. Downtimes due to the low availability of sensors or due to unnecessary cleaning and unplanned service deployments are a thing of the past.

Predictive maintenance offers a precise outlook for the future

“The Monitoring Box is, amongst other things, an easy-to-implement gateway with software building blocks,” Dietrich said. “The TDC (Telematic Data Collector) is connected to the sensor on the quay crane via an Ethernet cable. Mounting the system is as easy as pie, even when retrofitting it.”

All the necessary data is sent into the secure cloud in encrypted form via LAN, WLAN or mobile communications and processed there. The customer now has the ability to monitor many statuses in real time from a smartphone or on the desktop and compare them to those of other networked cranes. The maintenance team can intervene in a timely manner when required or schedule maintenance. Actions are no longer dictated by the calendar, but rather by the actual status of the sensors.

SICK uses the recorded data to develop a forecast for the required maintenance. Predictive maintenance offers a glimpse into the future. It enables operators to know several weeks in advance what and when an event will occur and take suitable proactive measures.

Open and constructive collaboration with the experts from SICK in Spain

SICK Spain has collaborated with MSC Terminal Valencia for more than 10 years. In strategic industries like Ports, the specialized SICK local team works closely with customers on the optimal sensor solution. Thanks to this innovative IoT crane solution, the predictive maintenance will be improved and the downtime will be reduced. Campos said it took no more than three weeks to implement the solution on the cranes.

Dietrich explained that the right solution for the customer was found using a collaborative and agile development approach. The customer will be paying an annual system license fee to utilize the digital services from SICK. As confirmed by the Maintenance department at MSC Terminal Valencia, they were looking for an efficient, reliable and secure data solution. SICK offered Smart Data Solutions in technical expertise with individualized service.

![]() Want more information about Smart Data Solutions from SICK?

Want more information about Smart Data Solutions from SICK?