How MATEK used SICK sensors to increase productivity, prevent unnecessary machine stops, and support machine operators

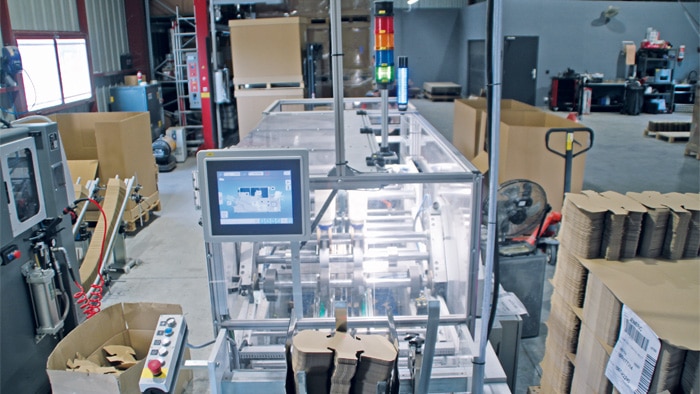

Machines from MATEK, an end-of-line machine specialist in France, ensure that cardboard trays are available quickly and efficiently, an increasingly important feat as the industry leans more toward cardboard packaging and away from plastic.

MATEK has been specializing in end-of-line machines and industrial equipment trading since 2015, with services ranging from spare parts supply to installation, troubleshooting, machinery improvement and maintenance. MATEK also provides support in designing specific machine parts, especially in the packaging industry. A few years ago, the company also purchased a machine for volumizing cardboard trays to meet the increasing demand for this type of packaging, as the latest European directives require a reduction in plastic packaging.

MATEK has been specializing in end-of-line machines and industrial equipment trading since 2015.

Optimizing machine productivity through ergonomics

The specific machine is a cardboard tray former: At the front, it takes the pre-cut cardboard flat from the loading container, prepares it for volumization, applies the adhesive, and completes forming to produce a fully folded tray. An operator is required to fill the magazine at the front and release the stack at the end. The two stations are four meters apart. When operators are at the end of the machine, they cannot see the filling hopper. If it is empty, then the machine stops and reports an error, which greatly reduces productivity.

From this side of the machine, the operator cannot see the cardboard filling container.

To avoid this problem, Mathieu Hartmann, CEO of MATEK, first considered a distance sensor that would initiate a proper machine stop at a certain threshold distance. The Dx35 mid range distance sensor from SICK was perfect for this job. However, since innovation is a building block of MATEK’s DNA, a conversation with Emmanuel Renaud, Regional Sales Account Manager at SICK France, showed that the application could be improved even more. Why not warn the operator with a signal lamp and even a sound to avoid unnecessary machine stops?

The Dx35 mid range distance sensor from SICK initiates a proper machine stop at a certain threshold distance.

Time for setup: from unnecessary machine stops to increased productivity in only three minutes

This is how the SLT signal lamp became part of the project. The 21 colored LEDs now allow a single device to convey a slew of messages and warn the operator at different thresholds. The signal lamp is also equipped with IO-Link, as is the Dx35 mid range distance sensor. That is why Emmanuel Renaud suggested connecting the sensors to a SIG200 sensor integration gateway for easy configuration. And you can really see the result: It only takes three minutes to set up the sensor. “The detection, the blind zones, all the parameters of the sensors connected to the gateway are accessible. It’s amazing how easy it is,” says Mathieu Hartmann from MATEK. After connecting the signal lamp, it took another ten minutes to parameterize the color variations of the column.

How exactly does it work?

The Dx35 mid range distance sensor is mounted at the top and detects the stack of cardboard in the loading tray at the front of the machine. The SLT signal lamp then reports information about the height of the stack back to the operator:

- Flashing blue: The magazine is full/more than full

- Lights up green: The magazine is at 100%

- Gradual change of the colored section towards yellow between 100% and 50%

- Yellow: The magazine is at 50%

- Gradual change of the colored section towards red between 50% and 20%

- Addition of an acoustic signal (with the SLB Smart Light Buzzer module) to the red color: Between 20% and 18%

- Faster and faster flashing between 18% and 1%

- Below 1%, the machine stops picking up cardboard, but does not stop (no unnecessary restart of the machine)

- When this level is reached, filling the magazine and pressing a button is enough to restart the machine

Of course, the goal is to never reach 1% so that productivity is not endangered.

Trays are out, the results are in: 5% increase in machine productivity

The subtlety of the machine parameterization is possible thanks to the performance of the SIG200. Since the controller is also connected to the sensor integration gateway, the conditions for stopping the machine can also be set. “The result exceeded my expectations,” explains Mathieu Hartmann. This holistic solution has secured the production cycle, and Hartmann estimates that machine productivity has increased by 5%. The operator can better control the filling process and easily look ahead to what needs to be done. Comfort and ergonomics are motivating factors for an operator. Seeing that one of the operators actively participated in the parameterization of the colors, MATEK has a lot of confidence in the machine.

Thanks to the SLT signal lamp, the operator knows when to refill the container.

Trust + collaboration = intelligent solution

The key to the success of this project was above all the great sense of trust between Hartmann and Renaud. This trust allowed for open exchange and mutual understanding of the respective requirements. The simplicity and performance of SICK solutions during the demonstration did the rest.

Want to learn more about solutions like these?